REASON Reason for Joining YAMADA

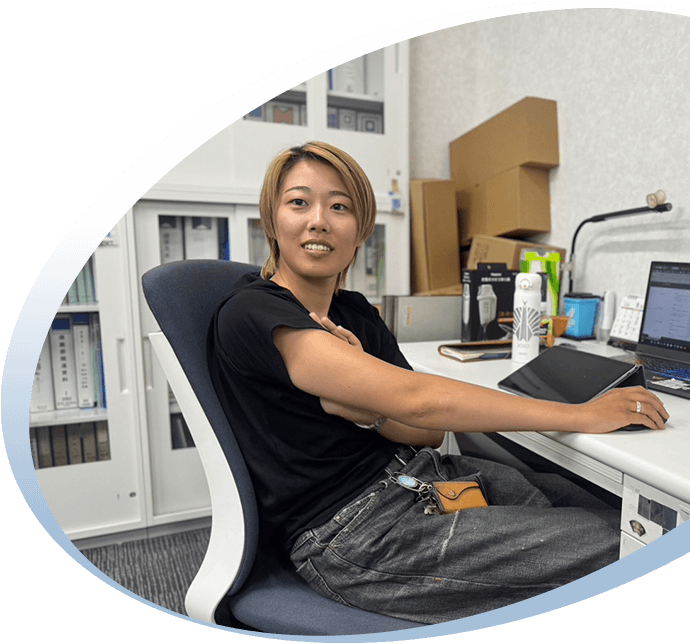

During my university years, I applied my knowledge of mechanical engineering to product design, valuing the excitement of bringing ideas to life. In my job search, I looked for an environment where I could leverage that knowledge while being involved in a wide range of monozukuri. I was drawn to YAMADA’s integrated approach that allows us to be involved from development through mass production, and its corporate culture that empowers even junior employees to propose ideas, which led to my decision to join. The final deciding factor was the strong feeling that YAMADA would actively support and fuel my desire for growth.

FLOW Workflow after Joining

After joining the company, I started with OJT, learning how to read drawings and understand internal regulations alongside a senior colleague. Gradually, I was given responsibility for designing smaller parts and experienced the process of seeing my designs move into the prototype phase. Through numerous improvements based on feedback from senior colleagues, I was gradually entrusted with more responsible tasks. About six months later, I was assigned to design part of an entire product, which made me realize how much I had grown. YAMADA offers an environment where I can take on challenges step by step and develop skills with confidence.

JOB Current Work Responsibilities

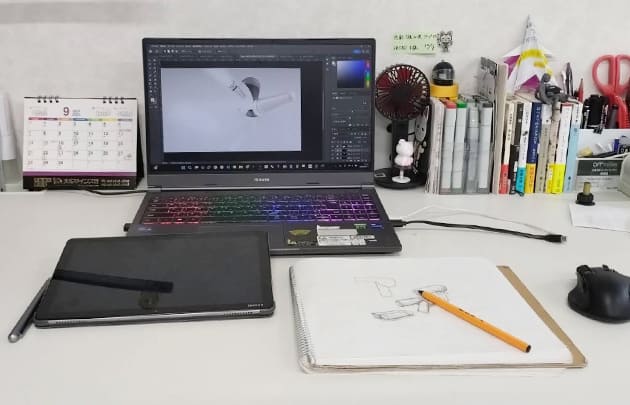

Currently, as a mechanical design engineer, I am engaged in the design of new products, from the initial development stage through to preparation for mass production. Specifically, my work primarily involves CAD-based design and structural analysis, along with continuous improvements based on prototype evaluations. When I first joined YAMADA, I felt anxious, wondering if I could really do this job. However, during review sessions, my senior colleagues always provided detailed advice and encouraged me to take on new challenges. Recently, a design improvement I proposed was adopted and incorporated into a product’s specifications, giving me a strong sense of accomplishment. While I still have much to learn, I am continually striving to fulfill my responsibilities and contribute as a member of the team.

REWARDING Rewards and Personal Growth

I feel great joy the moment the parts I designed take shape and begin to function as part of a finished product. I get especially excited when holding a prototype in my hands and seeing how the design image from the drawings has been fascinatingly transformed into reality. Furthermore, the environment allows me to be involved not only in design but also in product proposals and improvements. It widens the scope of my learning and allows me to genuinely feel my growth. Through advice from senior colleagues and on-site experience, I feel my perspective as a designer is gradually broadening.

VISION Future Goals

In the future, I aim to become a designer who can lead the entire product development process. To achieve this, I will continue taking on new challenges and building broad knowledge and experience, striving to become someone my junior colleagues can rely on.

A Typical Day at Work

- 8:50

a.m.Arrive at the office - 9:00

a.m.Check Emails:

Organize today’s tasks. - 9:30

a.m.Department meeting:

Share the progress of assigned products. - 10:30

a.m.CAD design work:

Create drawings for part designs assigned by senior colleagues. - 12:00

p.m.Lunch break

- 1:00

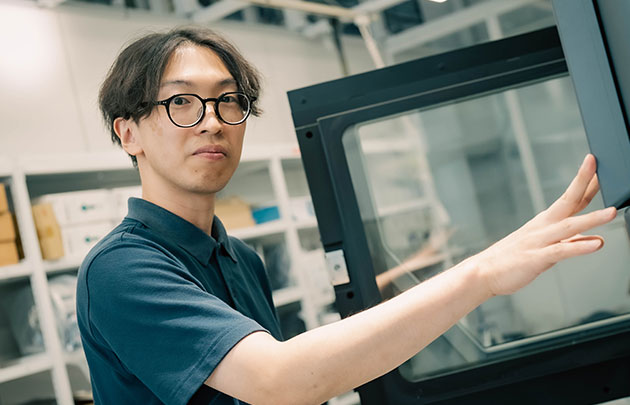

p.m.Prototype inspection:

Check prototype parts sent from the factory in China with a senior colleague. Inspect whether the design intent has been reflected and take notes on points for improvement. - 3:00

p.m.Design review:

Submit drawings to my supervisor and project leader. Review suggested modifications based on feedback. - 4:30

p.m.Design revision work:

Reflect feedback received during the review. Reorganize the data to prepare for the next submission. - 7:00

p.m.Leave the office: Work overtime for about one hour.

Overview After Joining YAMADA

-

-

Under the guidance of senior colleagues, you will learn the overall workflow by reviewing design drawings and product specifications.

-

-

Once you became familiar with the process, you will start handling partial designs for small parts and structural components, as well as drawing modifications. You will begin to realize that you are engaged in a part of each product through collaboration with your team.

-

-

At this point, you will become engaged in the entire product development process —from upstream to downstream— covering specifications coordination with customers, mold procurement, prototyping, evaluation, and the ramp-up of mass production.